This one day course has been designed to provide an initial understanding of the concepts relating to the use of hot dip galvanized coatings as applied for corrosion control of carbon steel components. The course is presented as an introduction to the more advanced and detailed three day qualification course needed for registration as a recognised hot dip galvanizing inspector.

Bookings are limited and will be treated on a first-come-first-serve basis. Please note that in order for the course to be viable we require at least six (6) candidates to attend. Arrangements can also be made for the course to be held at your premises for more than six (>6) candidates. The course is designed to provide a solid foundation for candidates before undertaking the more demanding three day Level II aka Inspector’s course.

The course comprises six lessons, each of approximately 45 minutes duration. The course is concluded with a one hour examination designed to test course effectiveness. A standard grade pass of 50% is required to receive a certificate of completion. Should delegates perform well in the exam i.e. a final aggregate score of > 75%, higher grade pass, they will be eligible to attend the Level II course at a discounted fee.

Course Content

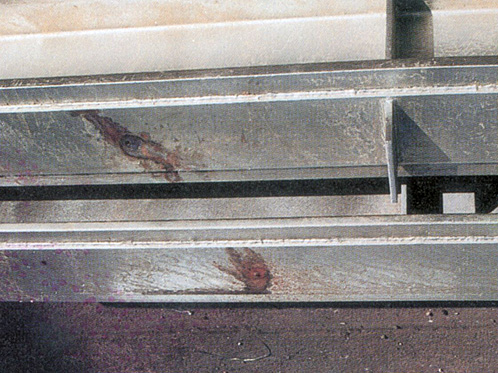

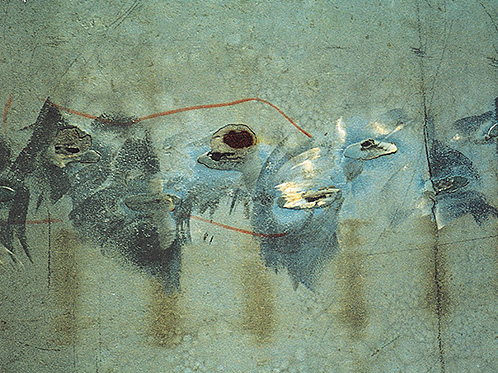

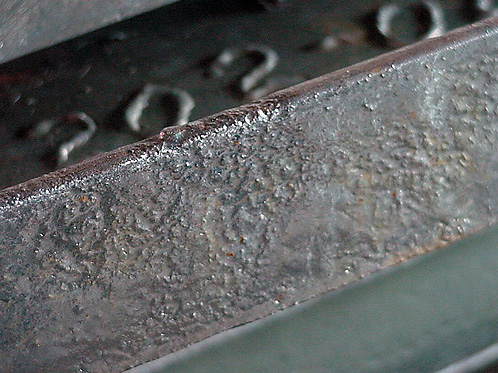

- Introduction to corrosion

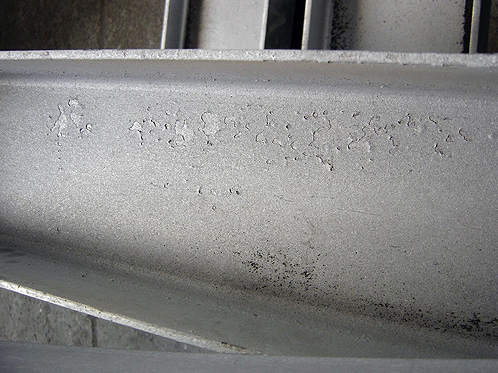

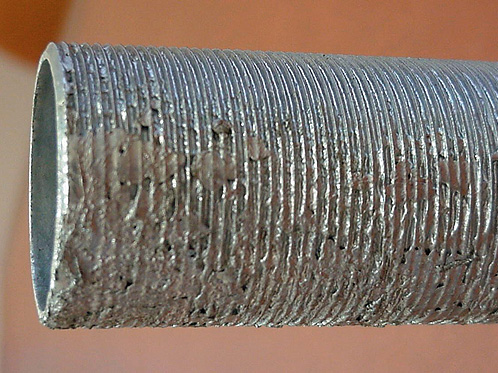

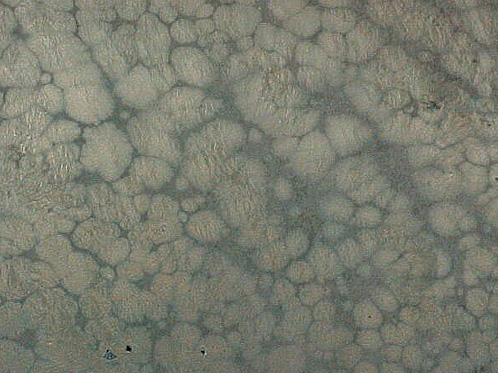

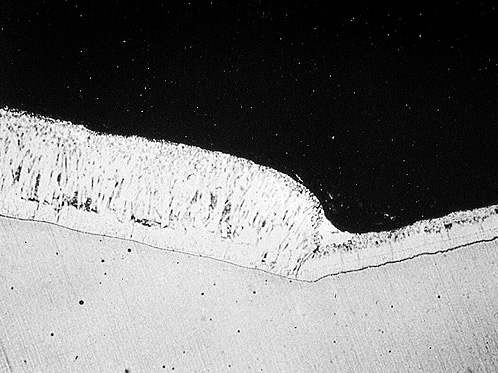

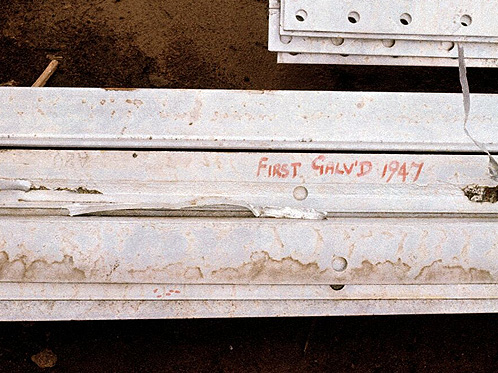

- Understanding hot dip galvanizing & Zinc coatings

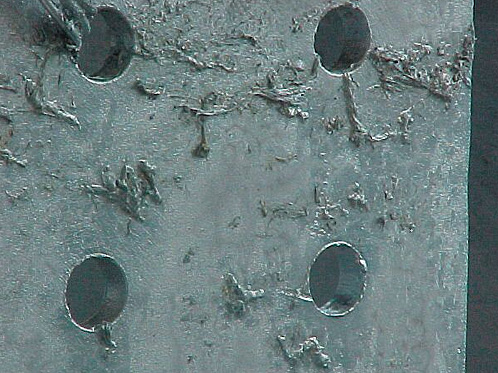

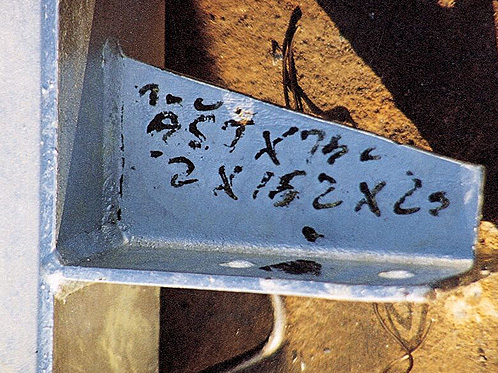

- Inspection and jigging before hot dip galvanizing

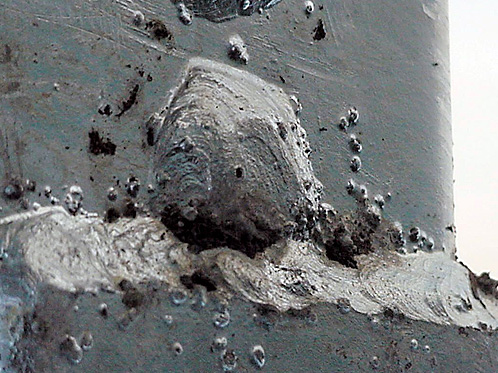

- The hot dip galvanizing process

- Inspection after hot dip galvanizing

- Maintenance and controls

Course Duration

This is a one day course comprising six lectures and a one hour examination designed to test the effectiveness of the course.

Time

The course commences at 08h00 sharp and ends at 18h30. Lunch and refreshments will be provided.

Course Cost and Payment Terms

A fee of R1850.00 per person excluding VAT applies. Should you have 2 or more delegates from the same company, course costs will be R1650.00 per person excluding VAT.

Note: Terms are on a strict payment before attendance basis, unless by special prior arrangement. Upon receiving your Training Booking Form a reservation confirmation will be sent to the delegate as well as an invoice made out to the payee,Failure to attend the course without a two week prior advice will levy a 50% charge to cover logistical expenses incurred,No refunds or credits will be entertained for any withdrawal. Only one postponement will be granted.

| T: +27 (0)10 746 8927 | E: hdgasa@icon.co.za

| T: +27 (0)10 746 8927 | E: hdgasa@icon.co.za